We know all about that.

Also for your industry!

Positioning systems

02

Gantry and microscope stages form the foundation of all ITC positioning systems. Gantry tables are usually of classic gantry design and are used wherever relatively light workpieces and specimens have to be positioned with high precision and dynamically. The same components are used in microscopy, but in a much more compact design. The latest microscope stages have five active axes to provide the best possible support for fully automated laboratory operation. Our product portfolio thus ranges from small dimensions under the microscope and samples in the gram range to four-square-metre scanning systems with up to eight active positioning axes.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

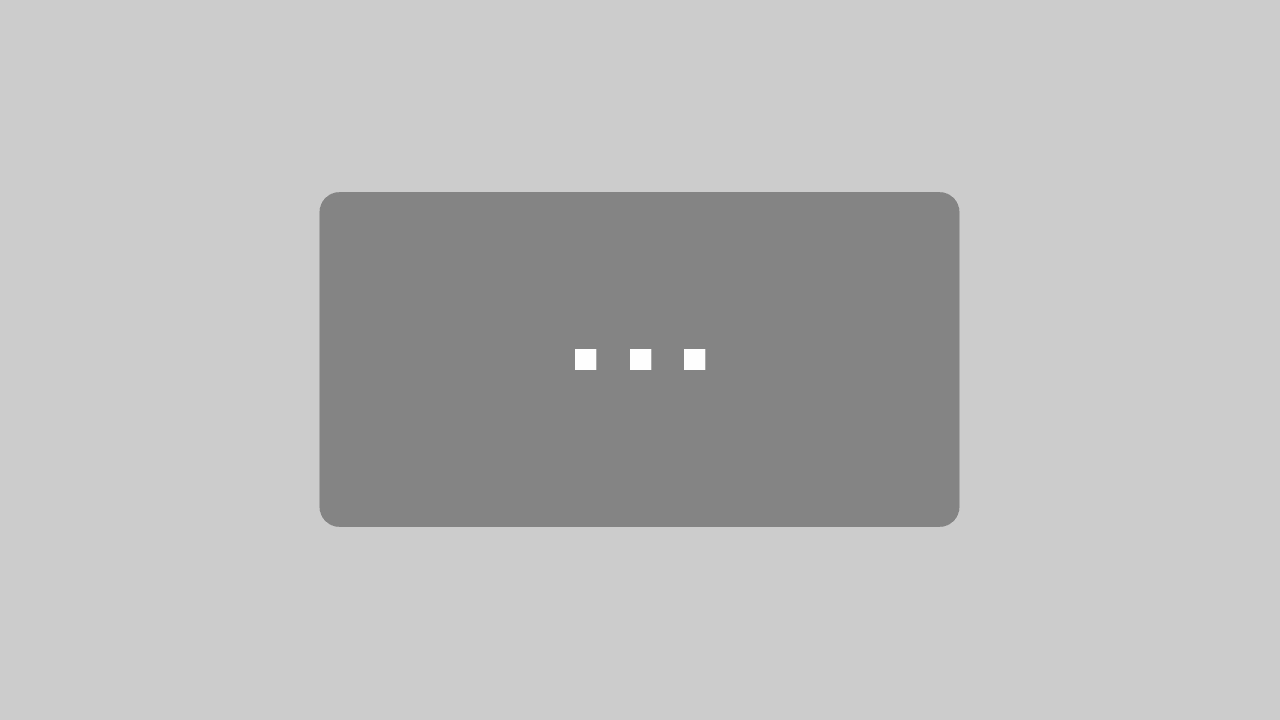

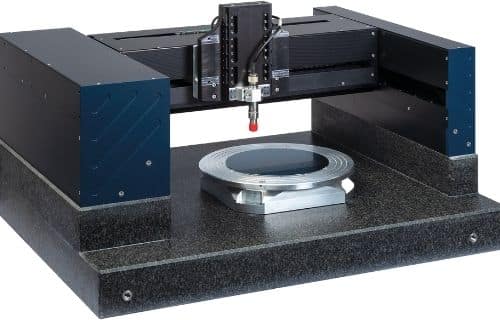

Gantry systems from ITK belong to the SensePrecisioner® product family. The products of the PT15 series, available in various basic versions, form the basis for positioning with systems from ITK. Optimising each system flexibly and according to customer requirements – that is our speciality. Thanks to the modular design and the use of our own components, we can offer you a customised solution based on your specifications. All the systems we use have one thing in common: they are 100 percent cleanroom compatible and absolutely reliable – even in continuous 24/7 operation. Scanner areas of up to 4 m2 are available as standard, larger areas are available on request.

Accessories

Of course, our PT15 positioning systems can be optionally extended with various Z-axis modules. The axis modules are driven by linear motor or spindle. In addition, we offer corresponding measuring systems. The assembly of the required Z-axes can be done by the customer.

ITK provides you with a complete solution: from consulting to commissioning, you receive everything from a single source and made in Germany.

PT-15 Variant | Repeatability | Positionioning accuracy | Resolution | Travel speed | Acceleration | Max. capacity [kg] |

|---|---|---|---|---|---|---|

-A | ■ ■ | ■ ■ ■ | ■ ■ ■ | ■ ■ | ■ ■ | 2-8 |

-B | ■ ■ | ■ ■ ■ | ■ ■ ■ | ■ ■ | ■ ■ | 2-10 |

-C | ■ ■ ■ | ■ ■ ■ | ■ ■ ■ | ■ ■ ■ | ■ ■ ■ | 2-8 |

-G | ■ | ■ | ■ ■ ■ | ■ ■ | ■ | 2-10 |

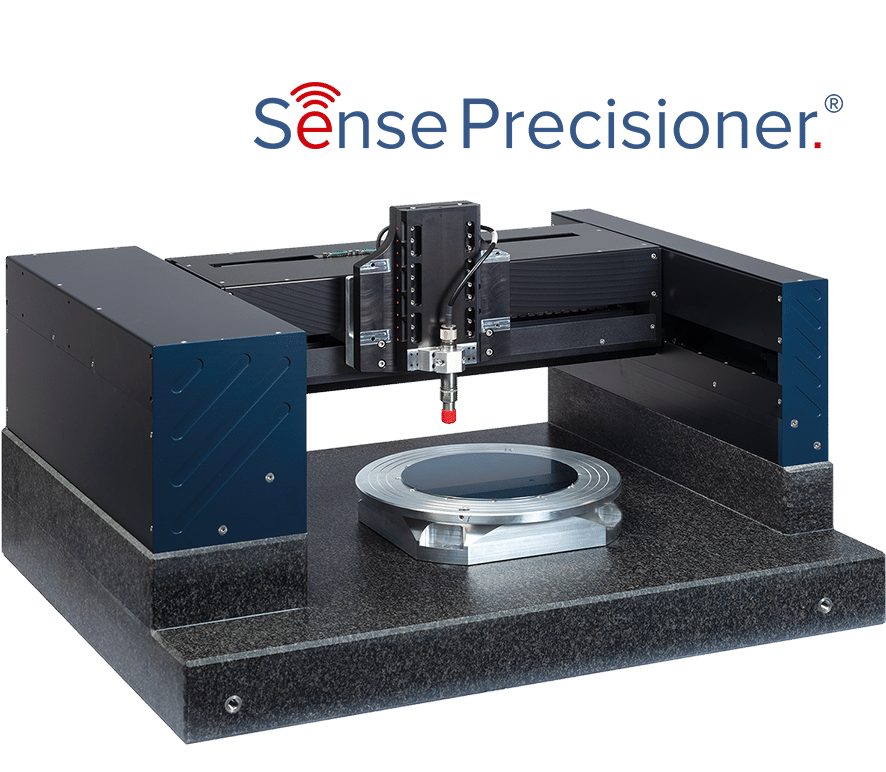

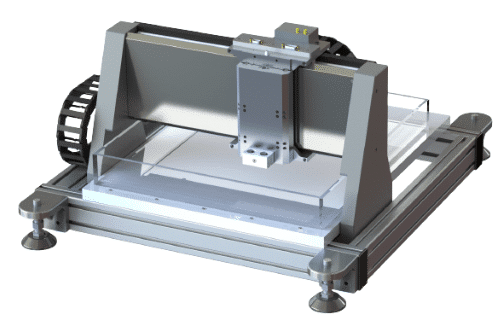

Gantry systems from ITK belong to the SensePrecisioner® product family. The FBS series (flatbed scanner) is the cost-effective entry-level model in ITK’s 3D positioning world. Available in various basic versions, the FBS series offers an easily configurable, cost-effective basis for three-dimensional X-Y-Z scanning movements.

The X-direction is driven by a highly dynamic linear motor, the Y-direction is optionally driven by a linear motor or stepper motor with spindle and the Z-direction by a spindle drive with shaft joint and stepper motor. In particular, the use of linear motors in combination with magnetic length measuring systems and the modern control system (ITK Andromeda or Hydra) enables outstanding dynamic properties and extremely fast computer access. Special accessories, such as a joystick and/or a handwheel (both based on CAN bus communication), ensure easy and ergonomic operation. The 100 MBit/s Ethernet interface allows fast access to the data stream from the scan sensor.

Optimising each system flexibly and according to customer requirements – that is our speciality. Thanks to the modular design and the use of our own components, we can offer you a customised solution based on your specifications.

Accessories

Of course, our FBS positioning systems can be optionally operated with various accessories such as handwheels and joysticks.

ITK provides you with a complete solution: from consulting to commissioning, you receive everything from a single source and made in Germany.

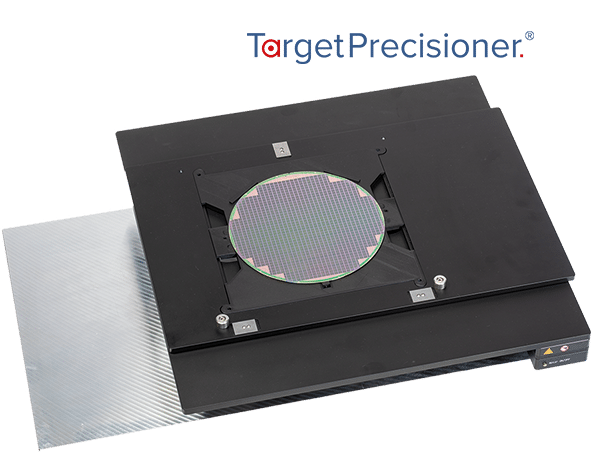

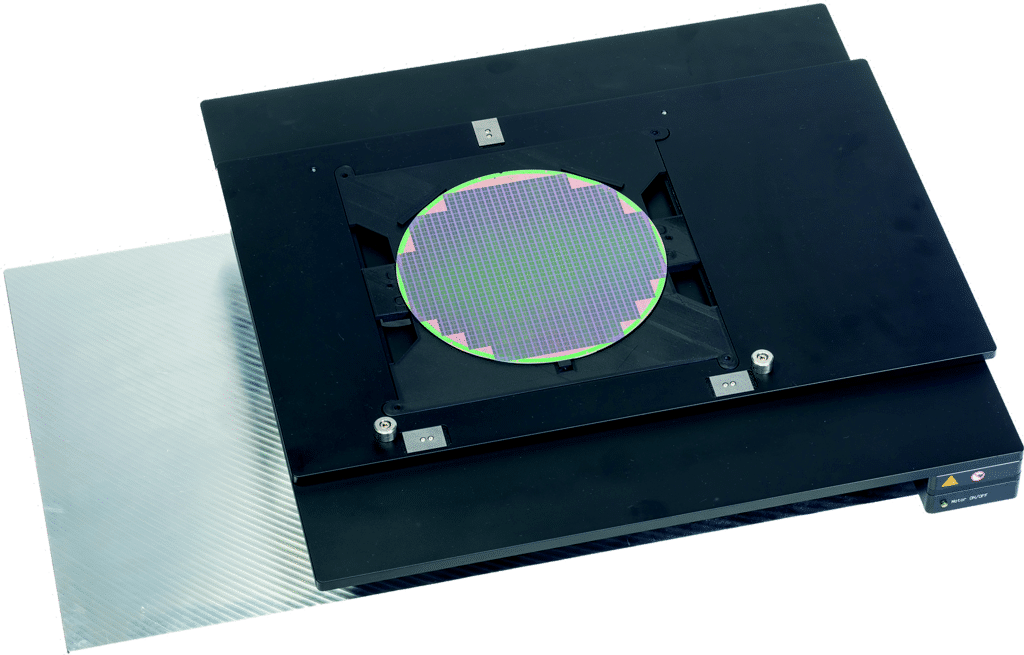

Microscope stages from ITK belong to the TargetPrecisioner® product family. Our microscope stages are equipped with various features that make them particularly user-friendly and enable reliable positioning. These include easy parameter setting and precise repeatability of travel patterns. The operator can choose between manual and automatic operation. The microscope stage can be operated by hand wheels or joysticks, which are optionally available from ITK. The high spatial accuracy and resolution in image generation is ensured by a special, extremely fast trigger function in the control unit developed to match the stage. Robust sensors based on the magnetoresistive (MR) effect ensure high precision and dynamics. The equipment includes a highly dynamic linear motor with a new design that ensures maximum performance in the smallest space. Silent, fast and wear-free.

Product | W = Design | X = Upright/Inverse | Y = OEM-Variant | Z = Variant |

|---|---|---|---|---|

LMTWXY-Z | 2 = Standard version 3 Plates; (120 x 80) mm | 0 = Invers | 0 = Leica | T = Titan |

3 = Microdissection | 5 = Upright | 1 = Zeiss | F = Frontloader | |

8 = 8 inch (203 mm) Travel path | 6 = Stereo | 2 = Olympus | HS = High Speed Trigger | |

3 = Nikon | VX = Version 1, 2, 3, etc. |

Am Römerlager 5 | D-35633 Lahnau

SIE MÖCHTEN AUF DEM LAUFENDEN BLEIBEN?

DANN ABONNIEREN SIE UNSEREN NEWSLETTER!

YOU WANT TO STAY UP TO DATE?

THEN SUBSCRIBE TO OUR NEWSLETTER!

Technical Data

Parameter | Unit | Typical performance characteristics |

|---|---|---|

Travel speed in X | m/s | 0.5 … 2.5 |

Travel speed in Y | m/s | 0.5 … 0.8 |

Acceleration in X | m/s2 | 5 … 50 |

Acceleration in Y | m/s2 | 0.5 … 5 |

Repeatability bidirectional | µm | ≤ ±0.5 … ≤ ±2.5 |

Positioning accuracy bidirectional | µm | ≤ ±10 … ≤ ±50 |

Resolution | nm | 50 … 500 |

Technical Data

Parameter | Unit | Typical performance characteristics |

|---|---|---|

Load capacity | kg | 0.5 … 5 |

Travel speed in X & Y | m/s | 0.25 ... 1 |

Acceleration in X & Y | m/s2 | 0.5 … 10 |

Repeatability bidirectional | µm | ≤ ±1 |

Positioning accuracy bidirectional | µm | ≤ ±20 … ≤ ±80 |

Resolution | nm | 500 |

Technical Data

Parameter | Unit | Typical performance features |

|---|---|---|

Travel speed | mm/s | 0.1 … 500 |

Acceleration | mm/s2 | ≤ 1000 |

Repeat accuracy | µm | different classes |

Position resolution | nm | 5 |

Travel range | mm | 50 x 50 … 205 x 205 |

The SensePrecisioner® product family includes all positioning systems from ITK in which a sensor is precisely positioned relative to the object or workpiece being tested, such as our PT15 and Eco Gantry series gantry tables. The trademark is made up of the terms Sense for sensor, Precision for precision and Positioning.

The TargetPrecisioner® product family includes all positioning systems from ITK in which a sample or workpiece is moved relative to the sensor, such as our microscope stages. An example of this is the LMT series. The trademark is formed from the combination of Target or sample, Precision and Positioning.